Pantera

Club

|

Colorado Pantera Club |

||

Rebuilding a Ford 351 Cleveland

Part 3: Ford 351C Component Inspection

| Now that my 351C is in "kit form" it's time to take a look at everything and do some forensics into what went wrong. - Matt Hannes | ||

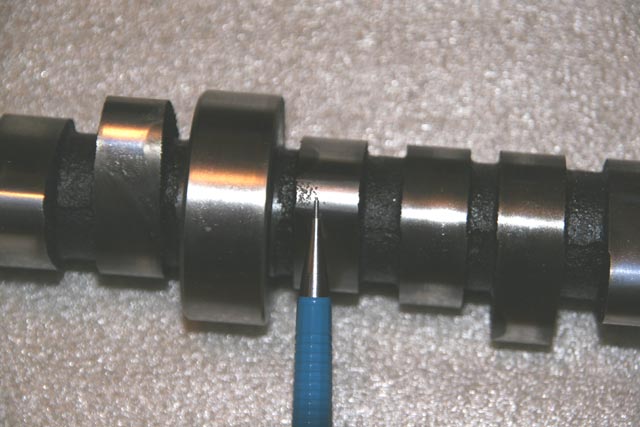

Camshaft. This was the main reason for my engine rebuild. The Pantera started running poorly about a year ago. It started idling rough, then it was low on power and backfiring. Towards the end, it would barely even run at all. After spending many weekends checking ignition and carburation, I decided it was probably something internal. Some buddies checked out my car and suggested camshaft failure as the likely culprit. So finally we measured the push rod lift to check the cam.

We pulled the valve covers and used a dial gauge to measure push rod lift while somebody turned the crankshaft by hand with a big breaker bar. The lift readings on each push rod varied greatly, so we knew the camshaft lobes were wearing unevenly. Then I removed all the front engine accessories and pulled out the camshaft. The photo above is what I found. Many lobes were substantially worn down with significant surface pitting. The flat-tappet lifters were also clearly worn out with concave bottoms. Some lobes were worn by over 0.150". I wasn't thrilled to think about all that metal mass floating around in my oil system, so I decided it was time for a teardown. Besides, I had never been into my engine before and I had zero documentation on the engine, so I figured it was also a good opportunity to inspect everything and see if anything else needed replacing.

| Heads. Ford offered several different styles of heads for the Clevelands with varying combustion chamber sizes, port sizes, valve sizes, and rocker arm types. Panteras typically only got equipped with two types. The early cars (1971) got the 4V "Quench" heads with small combustion chambers. 1972+ Panteras got the 4V "Open" heads with large combustion chambers for lower compression ratios and better emissions. Mine are 1973 "Open" head castings, as evidenced by the large open combustion chambers and D3ZE-AA casting code. Ports are 2.50"x1.75" (intake) and 2.00"x1.75" (exhaust). Valves are 2.19" (intake) and 1.71" (exhaust). You'll see the valves are caked with carbon. Some of this is probably from the poor combustion caused by the failing camshaft. Some is also probably caused by my oversized 750cfm 4bbl carburator. I plan on dropping down to a 600cfm carb after this. |

|

||

|

|||

| Block casting code. There is some good information available here. D2AE-CA is a Cleveland design code. "D" is the decade (D=1970s), "2" is the year of that decade (1972), "A" is the platform code (generic Ford) , "E" is the engineering group (Engine, in this case). "CA" is a Cleveland type code used from 1972-1973. The 3F30 is the casting date code. The first digit is the year of the decade corresponding to the design code - in this case it would be 1973. |

|

|||

| The second digit of the casting date code represents the month of the casting. Ford assigned an alphabet letter corresponding to the month of the year based on calendar order. So, January would be "A", February would be "B", March would be "C", and so on. In this case, "F" corresponds to June. The last two digits, "30", is the day of the month. So this block was cast on June 30, 1973.

Now, what does all this mean? Well, first of all, my car is not numbers-matching since my VIN corresponds to a November, 1972 Pantera...hence a motor cast in the summer of 1973 is obviously not original equipment. I already knew this when I bought the car, so it's not earth-shattering to me. The "A" platform code is a generic Ford code, so I don't know whether this engine was meant for a Pantera or if it was perhaps originally in a Mustang or Torino. At any rate, it doesn't really affect the value of a Pantera. The perpetually under-valued Pantera is one of the few classic cars where "numbers matching" has very little effect on market value. |

||||

| Take a look at the cylinder bores. I am looking for scratches or scores, especially along the line of piston travel. Some scarfing from the last hone (visible here) is OK as this helps the rings seat.

I measured the bore diameter with a caliper and it appears to have been bored 0.020" over. This is good since a Cleveland is a thin-walled casting, so 0.030" overbore is maximum. I will have the machine shop take more detailed measurements of the cylinders and crank. |

|

||

| Bearing caps. These are the beefy Cleveland 4-bolt main bearing caps. The Number 3 location has the crank thrust bearing. |  |

||

| Main bearings. These are the classic Clevite 77's. All looked good except for the Number 5 main bearing shown here. It had a couple significant scores across the surface. Regardless of how good the other bearings looked, they'll all be replaced with fresh ones. |  |

||

| Pistons and rods. My pistons are Keith Black KB149 hypereutectic domed pistons. The domes help bring the original 1973 Ford 9.0:1 compression ratio up into the respectable 10.5:1 range for these heads. They appear to be OK other than being caked with some carbon.

Rods are Ford D0AE Cleveland rods with high-strength ARP bolts. This set-up is fine for street engines, so I'll probably re-use them. New rod bearings will (of course) be installed. |

|

||

| Piston close-up. Here we see the carbon buildup on my domed pistons. |  |

||

| Rod bearings. Here's trouble waiting to happen: a couple of my rod bearings were worn down into the copper base. These definitely need to be replaced. |  |

||

Click here to return to the home page.

Contents copyright 2009-2010.